Quality

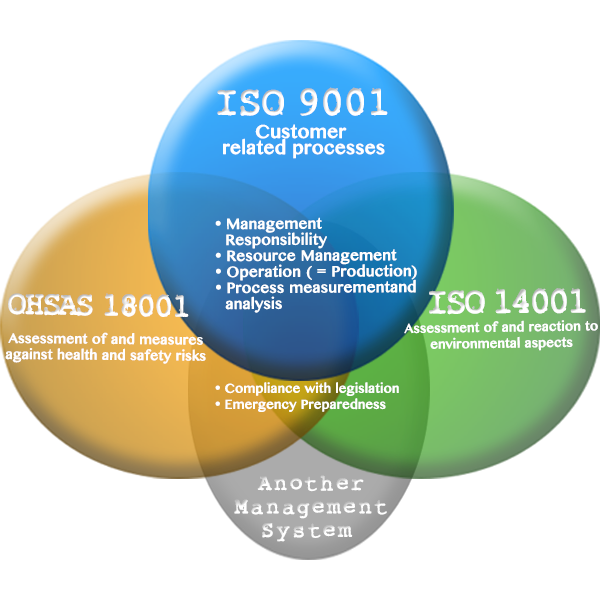

TNS having an Integrated Management System (IMS) integrates all of an organization's systems and processes in to one complete framework, enabling an organization to work as a single unit with unified objectives.

Organizations often focus on management systems individually, often in silos and sometimes even in conflict. A quality team is concerned with the QMS, often an EHS manager handles both Environmental and Health and Safety issues, etc.

Our BPEX (Business Process Excellence) team is continuously working on improvements of products and services considering dynamic market requirements.

• A well chalked out quality plan

• Quality plan is followed by all sections starting from raw material flow till finished material dispatches

• Quality plan is reviewed periodically

• Job specific quality plans are also drawn with inputs from customer

Some of the major heads of quality plan :

• Engineering and Drawing checks

• Raw Material checks

• In process checks

• Analysis of rejection and scrap

• Finished good checks – MS

• Finished good checks – Galvanized

• Dispatch checks

Skill Set Development Process

• Internal Technical Training

• On Job Training

• Internal certifications

• Maintaining fault record books and evaluation

• Review of Case studies

• HR trainings linked with personal skills

• ISO 9001 processes

• Training on Quality process

• Training on Project Management

• Cost control and make system effective

• Take corrective actions based on customer inputs

Special training for welders:

All welders are certified by internal as well as external agencies before taking them for the job.